-

Products

- Lab Instruments

- Lab Meters and Probes

- Chemistries, Reagents, and Standards

-

Online Analyzers

Ammonium Analysers Ammonia Monochloramine Chlorine Analyzers

- CL17sc

- CL10sc Amperometric

- 9184 sc Amperometric

- Ultra Low Range CL17sc Colorimetric Chlorine Analyser

EZ Series Analysers- Iron

- Aluminium

- Manganese

- Phosphate

- Chloride

- Cyanide

- Fluoride

- Sulphate

- Sulphide

- Arsenic

- Chromium

- Copper

- Nickel

- Zinc

- Ammonium

- Phenol

- Volatile Fatty Acids

- Alkalinity

- ATP

- Hardness

- Toxicity

- Sample Preconditioning

- Boron

- Colour

- Nitrate

- Nitrite

- Silica

- Hydrogen Peroxide

- EZ Series Reagents

- EZ Series Accessories

- EZ sc Series Inorganics

- EZ sc Series Metals

- EZ sc Series Nutrients

- Flow

-

Online Sensors and Controllers

Digital Controllers (Transmitters) Controllers (Analog)

- SC4500

- CA9300 Series Analog Transmitters

- Orbisphere 410/510 Carbon Dioxide

- Orbisphere 410/510 Oxygen

- Pro Series

pH & ORP Sensors- 12mm pH/ORP

- 8362 sc High Purity

- Combination pH/ORP

- Differential pH

- Digital Differential ORP

- Digital Differential pH

- LCP ORP

- LCP pH

- Sampling

- Multiparameter Online Panels

- Claros Water Intelligence System

- Test Kits & Strips

-

Microbiology

Prepared Media

- BARTS

- Liquid MPN

- MUG Tube

- Membrane Filtration

- Paddle Testers

- Presence-Absence

- Total Count Media

- Yeast and Mold

Dehydrated Media Kits Cryptosporidium & Giardia Analysis Legionella pneumophila Test Pseudomonas aeruginosa TestLabware- Accessories

- Funnels, Pumps & Manifolds

- Microbiology Filters

- Petri Dishes & Accessories

- Sampling Bags

- Vials, Tubes, Bottles & Racks

- Comparators

- Microbiology Accessories

- Microbiology Chemicals

- QC: Microbiology

- Quanti-Trays

- Sealer and Rubber Inserts

- UV Lamps

- Vessels

-

Lab Equipment and Supply

Apparatus

- Brushes

- Clamps, Rings & Stands

- Crucibles

- Crucibles & Casseroles

- Dispensers & Droppers

- Grab Samplers

- Oil and Grease

- Other Apparatus

- Pipet Aids

- Pipettes

- Racks

- Stir Bars

- Tubing

- Weighing Accessories

Instruments- Balances

- Hot Plates & Stirrers

- Microscopes

- Moisture Analysers

- Other Instruments

- Ovens & Incubators

- Thermometers

- Timers

- Vacuum Pump

- Automated Lab Systems

-

Environmental

Accessories Ambient Weather

- Kipp & Zonen Pyrgeometer

- Kipp & Zonen Scintillometer

- Lufft Ultrasonic Wind Sensor

- Lufft WS Series Smart Weather Sensor

- Lufft WS10 Series

Visibility and Present Weather Detection Hydrology Software Hydrology Water Discharge - Flow Road and Runway Sensors Solar Tracking and PV SoilingWater Level- OTT CBS Compact Bubbler Sensor

- OTT PLS Pressure Level Sensor

- OTT PLS(-C) Pressure Level Sensor with Conductivity

- OTT RLS Radar Level Sensor

- SUTRON Accubar Pressure Level Sensor

- SUTRON Constant Flow Bubbler

- SUTRON SDR Stage Discharge Recorder

Data Loggers and Telemetry- ADCON - Wireless Radio Communication / Telemetry

- Kipp & Zonen Data Logger

- SUTRON Antenna

- SUTRON SatLink 3 Logging Transmitter

- SUTRON XLINK 100 Logging Transmitter

- SUTRON XLINK 500 Logging Transmitter

- SUTRON XLite 9210 Datalogger

- SUTRON Xpert2 Datalogger

- Parameters

- Applications

- Industries

- Brands

- Service & Support

- News & Events

Industry - Electronics

Electronics

The electronics industry has stringent product quality requirements.

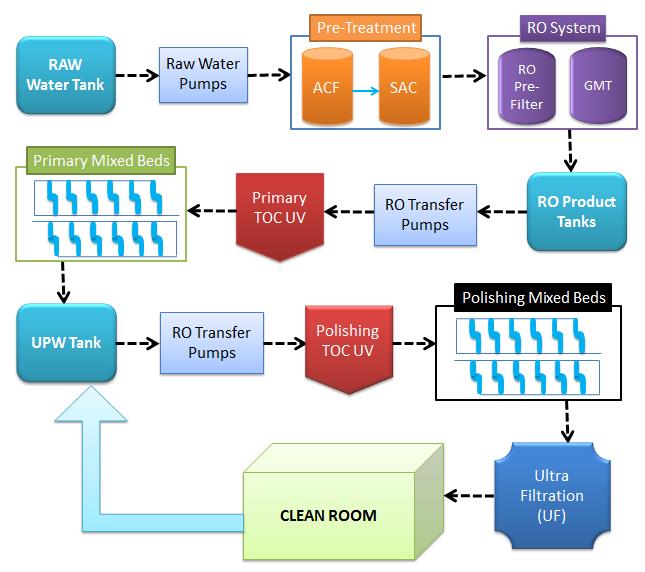

Microelectronic circuits are produced in extremely clean production environments known as clean rooms. Large quantities of high-quality ultrapure water are required in this industry. The water used to clean semiconductor wafers also needs to meet strict criteria. Since even the minutest particles can lead to production defects that could cause the failure of an entire circuit, highly sensitive measurement methods are vital.

Production with total purity

During the production of microchips, the first step is to create a substrate of monocrystalline silicon. This is then used to create discs or ‘wafers’ on which individual microchips are produced in parallel.

Whether rinsing or positioning the individual components on a wafer, the key factor in each stage of production is purity. This is because all processes need to be performed without any impurities present. Not only do airborne particles need to be monitored in clean rooms, but the rinsing agents have to be as pure as possible too. Simply de-ionising the water is not enough. Guaranteeing the quality of the ultra-pure water requires the use of highly sensitive water analyses. Even particles just micrometres in size can seriously impair the process.

As a world leader in water analytics, we have fully integrated monitoring solutions to address your water challenges related to the production performance, cost efficiency and sustainable development.

We provide our expertise in

- Process water like wafer polishing, clean rinse, dicing and back grinding

- Ultrapure water

- Wastewater

- Water Recycling & Reuse

- Energy & Chemical reduction

- Wide-range and high performance of sensitive TOC, silica analyzers etc. for UPW and reclaim water and silica control

Water cycle in Electronics industry and monitoring solution we are offering

Local case studies

Ensure quality with Hach – now!

Keep product quality high and operating costs low, and comply with the regulation as well through tight control of your water cycle and continuous measurement of water quality parameters!

Look at how we help these famous Southeast Asia electronic plants in their vital water cycles.